We help you become an innovative and cutting-edge leader in your industry

Our technologies allow you to keep up with the market and anticipate future scenarios

We guide you, with responsiveness and support, to improve your production performance

Our goal is to be a partner that leads each customer towards new trends in order to maximise production efficiency and increase the level of planning and scheduling of production flows.

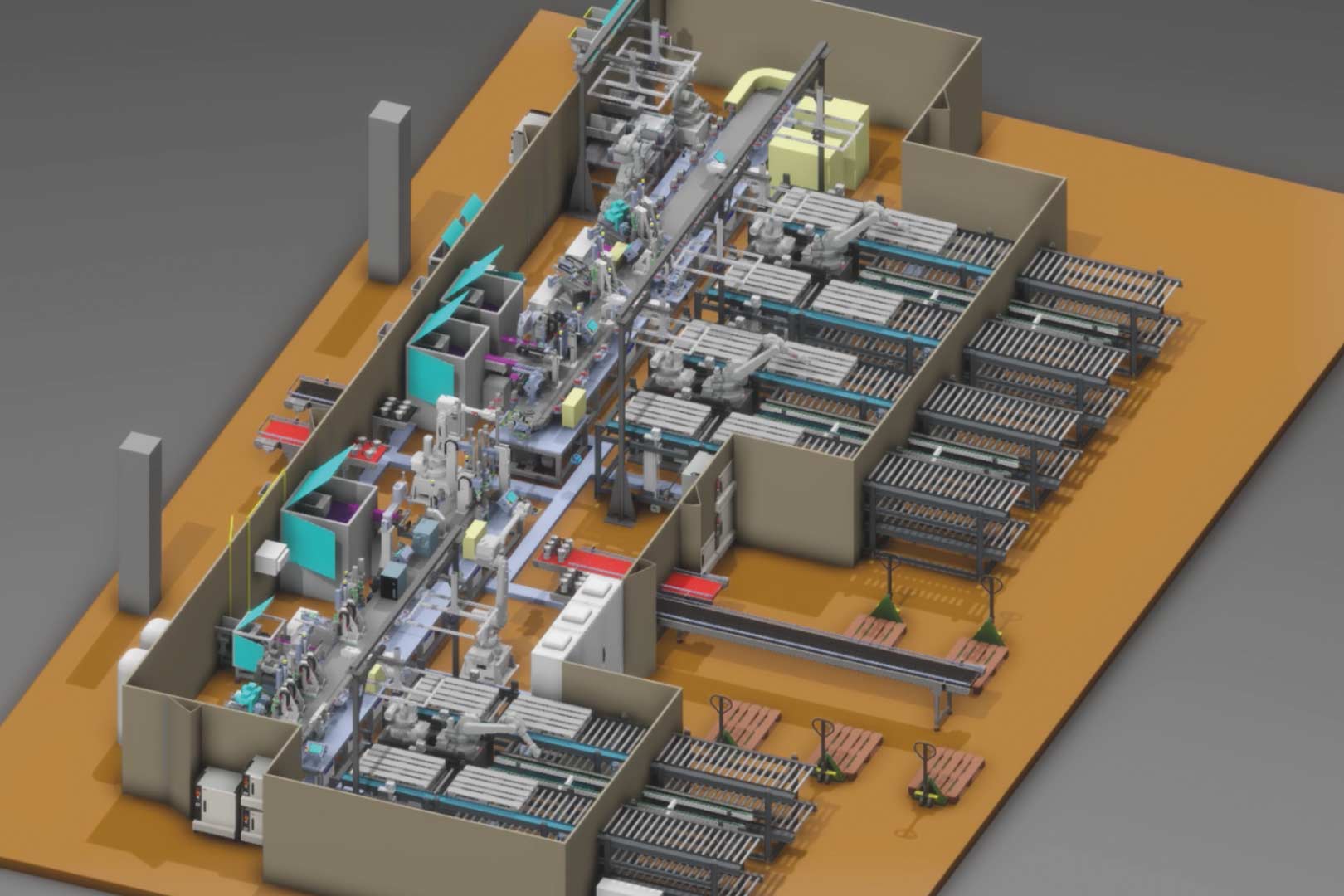

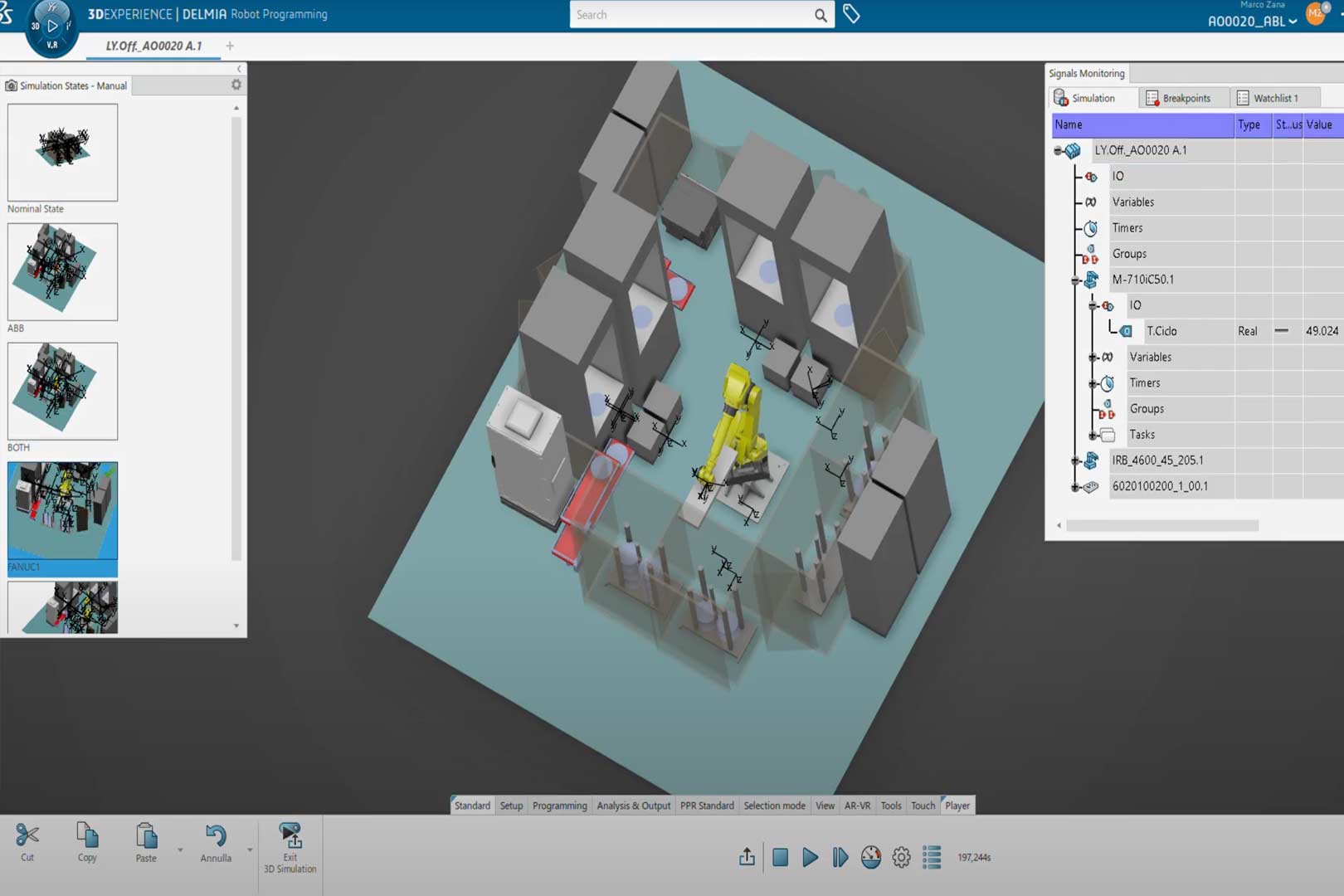

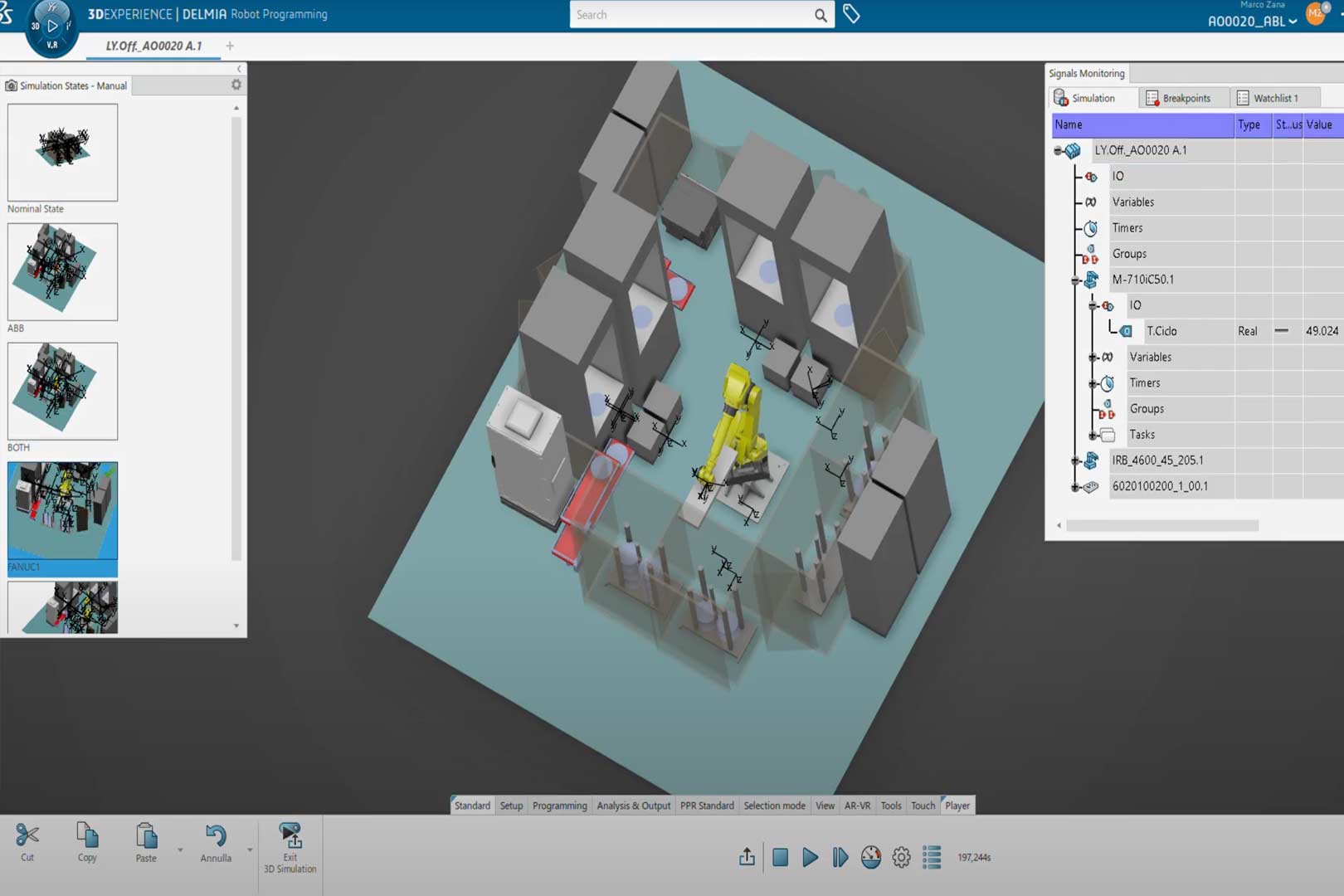

Digital Twin & Virtual Commissioning

A digital twin is a virtual copy of the designed line, created with the intention of reflecting, analysing and testing the system before its construction.

In addition to the traditional and consolidated integration methodology, we are strongly oriented towards this technology, which is fundamental for simulating, measuring performance in advance and generating valuable feedback to be provided to the real project.

This allows to:

- Objectively measure the performance of the system already during pre-sales and/or design phase;

- Define the processes in detail in a preventive way;

- Increase human-machine performance and improve production efficiency;

- Eliminate unforeseen events and, consequently, drastically reduce installation times and costs on-site;

- Simulate entire production plants.

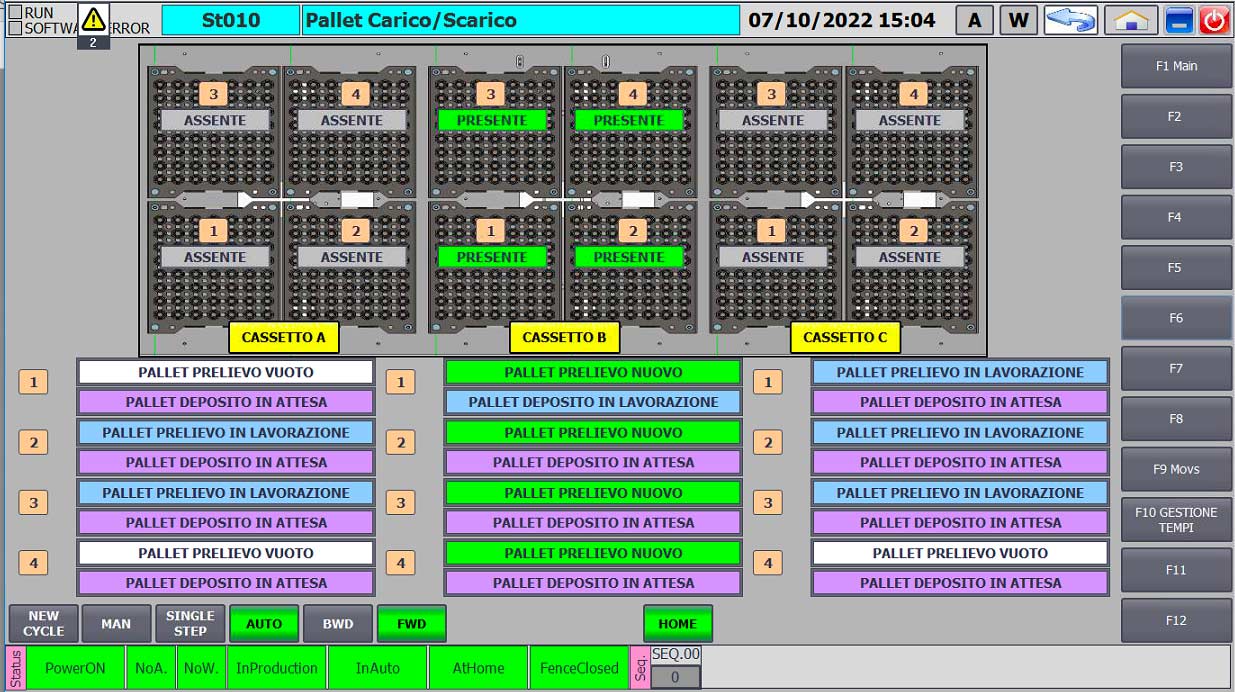

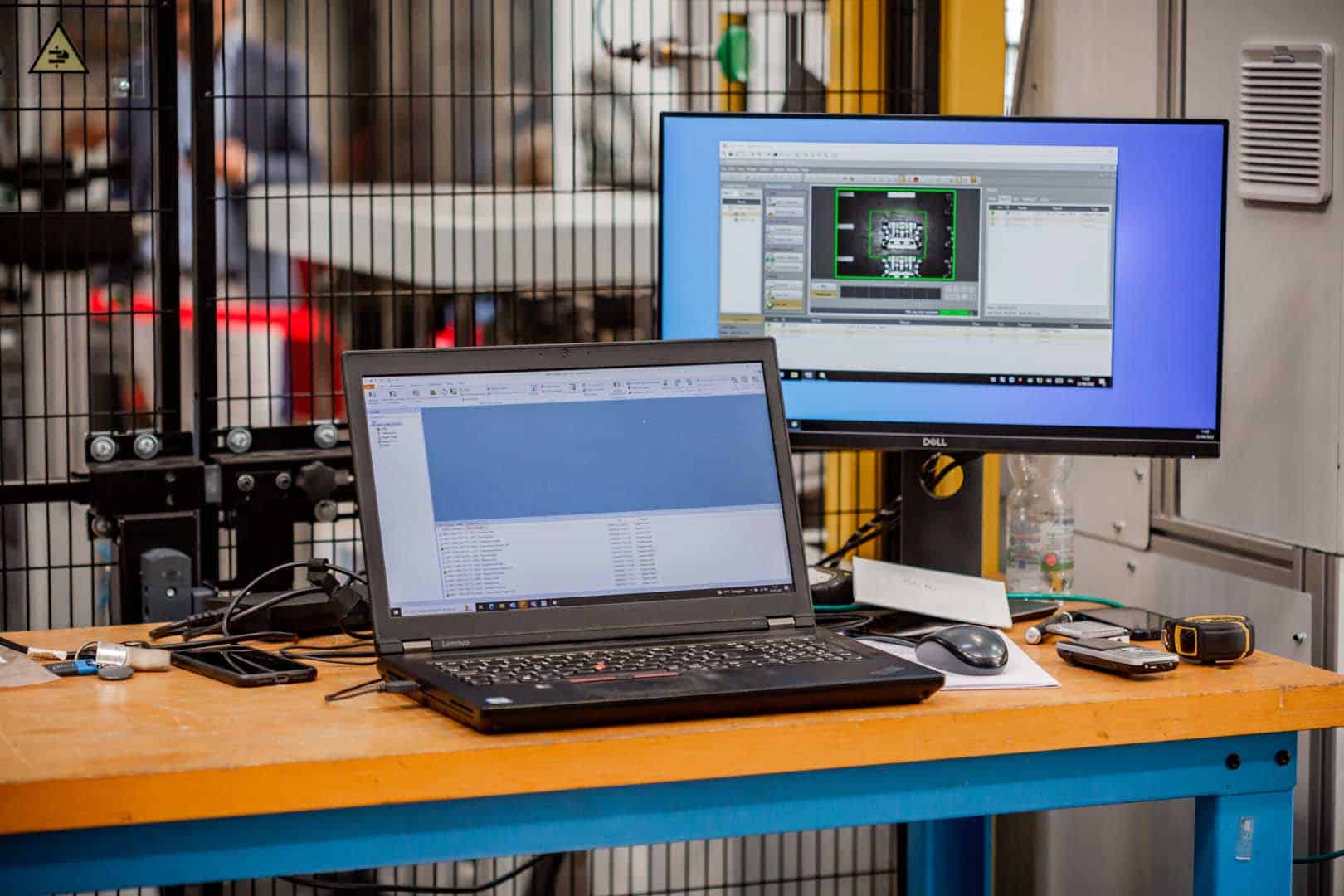

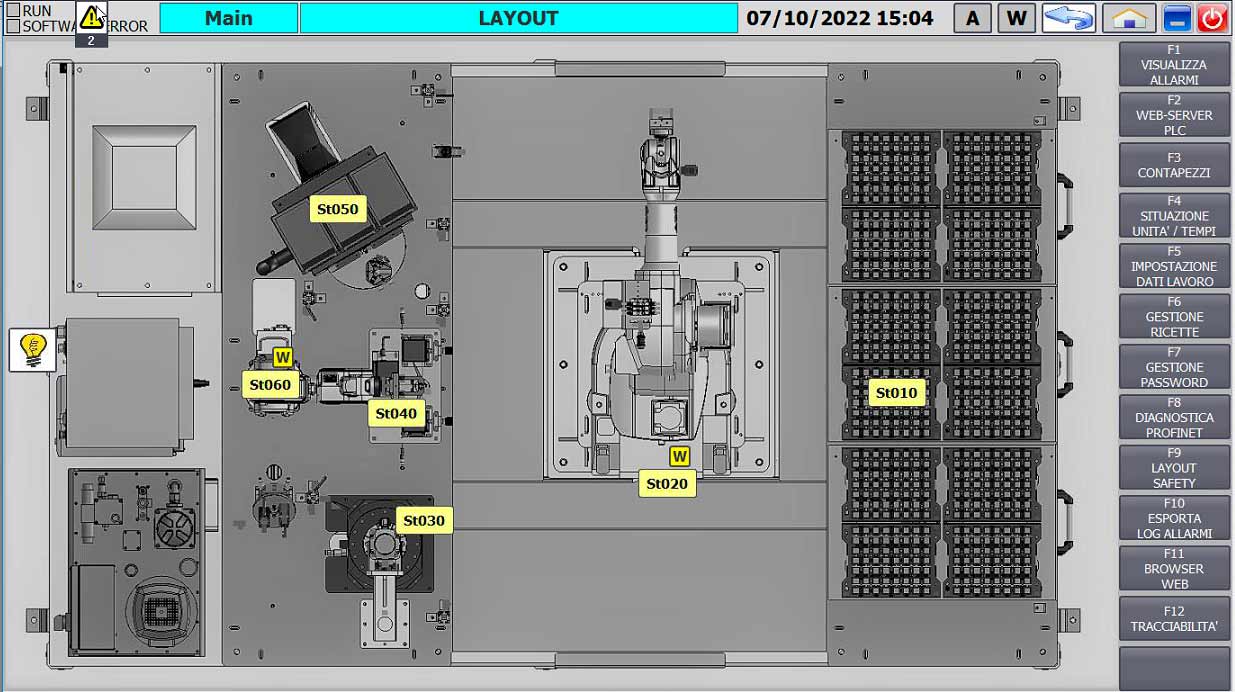

Supervision software

Our solutions are integrated with advanced, fully customised supervision systems, designed to monitor the performance and correct operation of the systems, as well as optimise and facilitate ordinary and extraordinary maintenance activities.

The perfect integration between latest-generation hardware devices and software applications, developed by our in-house technical team, enable the user to benefit, through an intuitive and user-friendly interface, a highly technological product for the “smart” control of industrial processes.

Among the main advantages are:

- Control of the system and/or process both locally and remotely;

- System data real-time collection, monitoring and processing;

- Direct interaction with all devices equipped on the line;

- Recording and storing system events and alarms in special log files;

- Creation of reporting files related to all system data.

Traceability systems

These systems are key functions in industrial automation and include recording information that describes the history and development of a product through all stages of processing, from raw material, to semi-finished and finally the finished product.

Today, traceability is an essential requirement for manufacturing companies; for this reason, with our customised and integrated software on the systems, it is possible to fully respond to essential needs.

Specifically, we use advanced tools such as:

- Laser marking technologies for alphanumeric codes or DMC Codes;

- Barcode/DMC Code printing devices;

- Verification and control systems;

- RFID radio frequency systems.

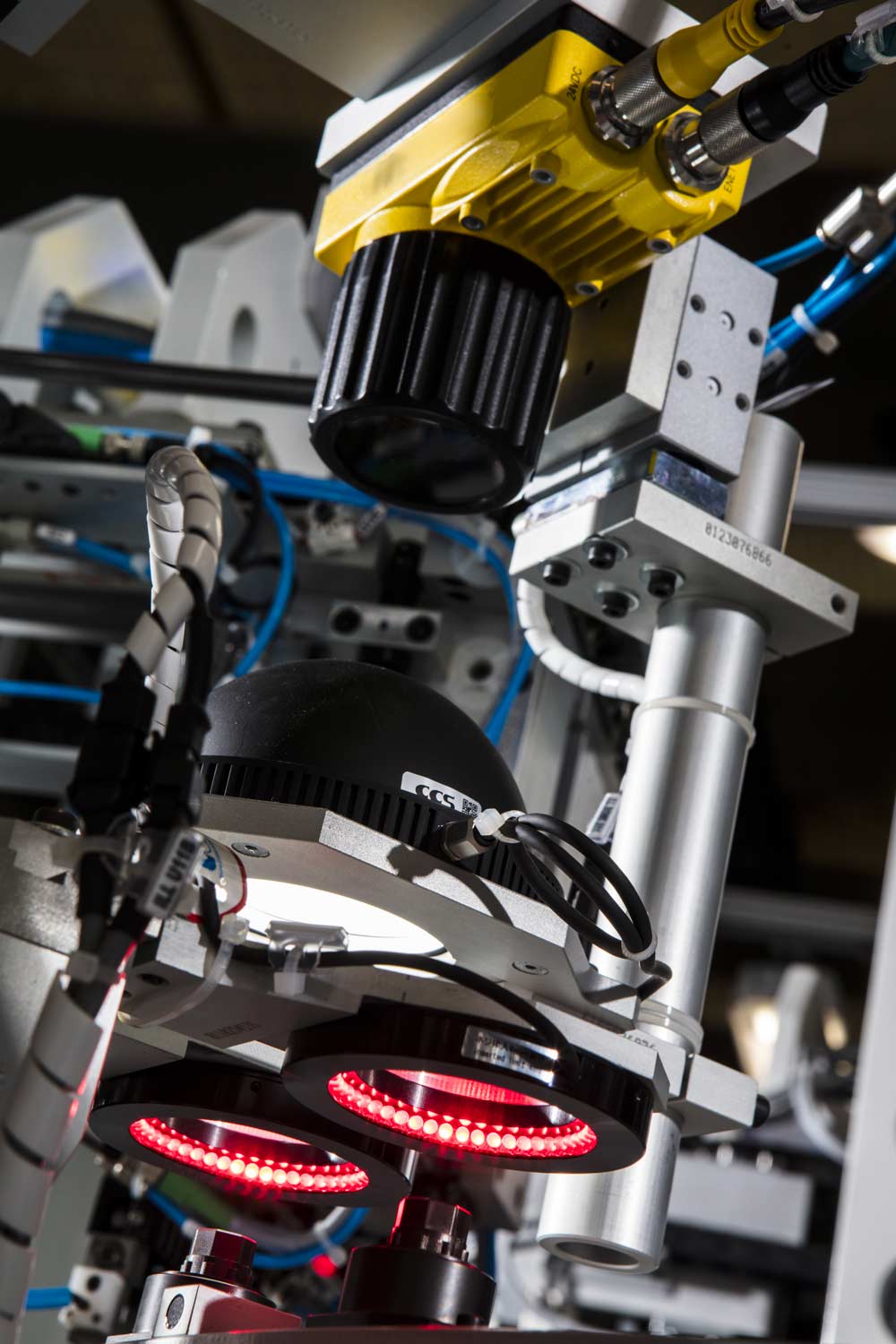

Vision systems and visual quality and process inspections

We offer a wide range of vision systems, selected and developed according to the application and the specific customer’s need.

The identification of the most suitable system, in addition to the definition of the relative lighting system, allows a high degree of customisation and adaptation to the different conditions of ambient brightness conditions.

These applications include:

- Robot - Drive (both in 2D and 3D version), for the identification of the position and orientation of details perfectly integrated with robot applications;

- Measurement, visual inspection and detection of defects for the interception of products that do not meet the required parameters;

- Presence or absence defection of objects in automatic applications;

- Integration of deep learning tools, based on modern concepts of artificial intelligence.

Remote assistance

To complete the after-sales services, our systems are all equipped with remote assistance service, for immediate remote support.

This approach makes it possible to:

- Optimise intervention costs;

- Drastically reduce system downtime and, consequently, lack of production;

- Give the possibility of continuously train automation management personnel.

Do you want to get ready for the future and become the leader in your industry?

We act as the main contractor for integrated solutions; we can support you through all the stages of designing your new automated system.

We are certified

We are certified