Machine tool tending

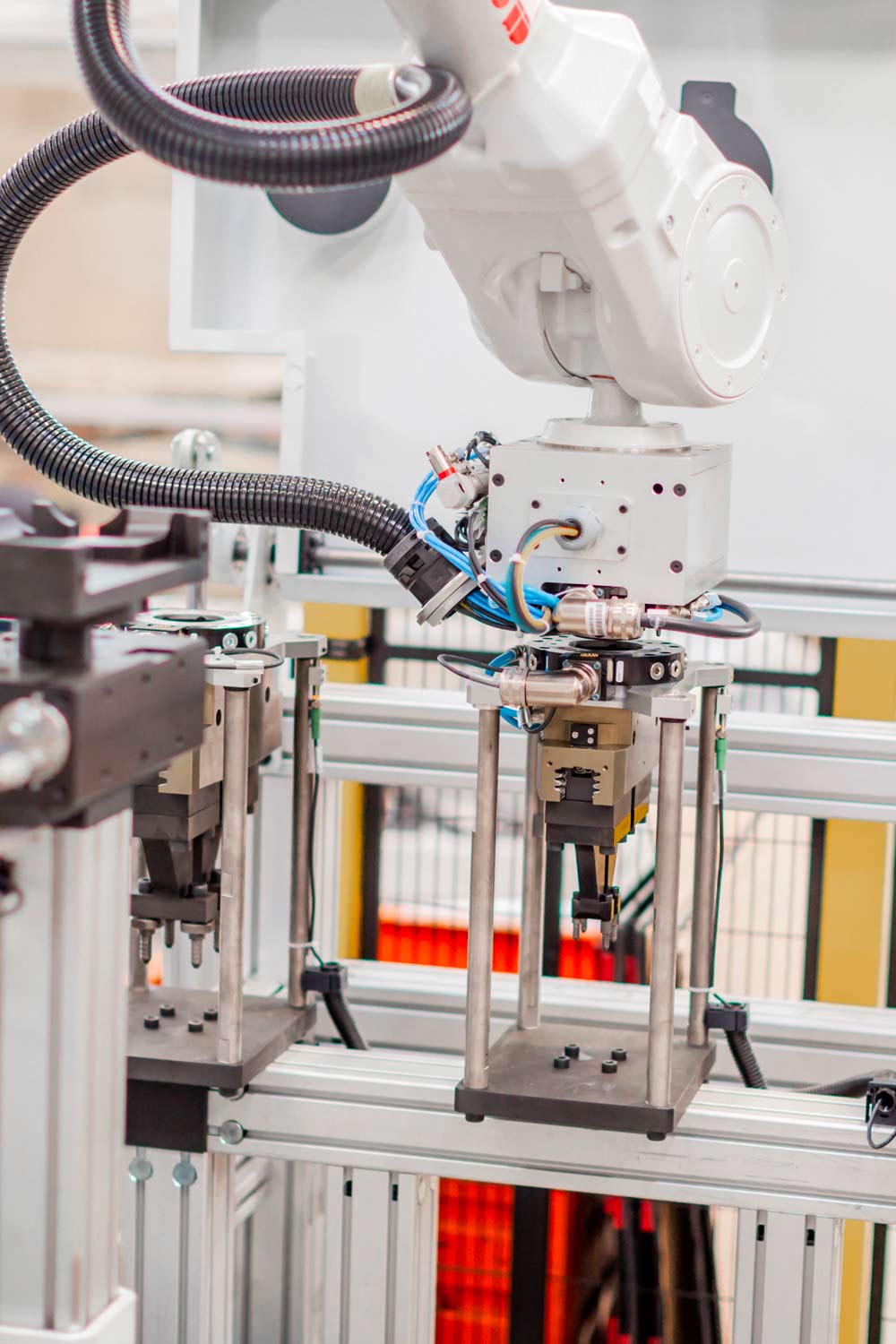

We design customized systems for machine tool tending that can be integrated with accessory operations.

Robotic production lines to increase productivity

We design customized systems for machine tool tending, such as transfer machines, lathes, machining centres, gear cutting machines and grinding machines.

These customer-tailored solutions allow each company to transform single mechanical processing cells into real robotic production lines in which they can integrate cleaning systems, dimensional and product quality inspections at 100%, objectification and traceability markings, up to the palletisation of finished parts ready for shipment.

The use of the most advanced vision systems, modular gripper change systems and flexible feeding systems guarantees minimized format changeover times, with an inevitable increase in the level of efficiency and flexibility of the lines.

Our machine tool tending systems guarantee:

- A high level of customisation and flexibility;

- Reduced set-up times;

- An increased level of autonomy;

- The integration of additional processes to mechanical processing;

- An integrated product inspection;

- The traceability of all products.

Sectors we work in

Automotive

Earth moving

Oil & Gas

Electromechanical

Energy

Hydraulic

Oleodynamic

Hydro-thermo-sanitary sector

Mechanical

Solutions we can achieve

Flexible machine tool tending solutions with the help of 2D and 3D vision systems

Machine tool tending solutions with automatic feeding systems

Complete production systems integrated with operations ancillary to mechanical processing (cleaning, dimensional control, inspection checks, leak testing, marking and palletisation)

Do you want to get ready for the future and become the leader in your industry?

We act as the main contractor for integrated solutions; we can support you through all the stages of designing your new automated system.

We are certified

We are certified