-

Risolviamo il tuo problema con soluzioni innovative e all'avanguardia

Ti aiutiamo ad arrivare prima di tutti con soluzioni non convenzionali e un approccio orientato alla realizzazione di una Smart Factory.

-

Il nostro impegno è garantirti una soluzione personalizzata in grado di accrescere il tuo livello di competitività

Curiamo ogni dettaglio in fase di engineering, nell’impiego di componentistica di primario livello e nella gestione dei programmi di manutenzione preventiva e predittiva.

-

Ti accompagniamo nel processo di digitalizzazione per trasformarti in una vera Digital Factory

La velocità è il nuovo valore del business e restare al passo con tecnologie e innovazioni è il segreto per crescere nel mercato.

Aiutiamo i nostri clienti a valorizzare le risorse, incrementare le competenze e rendere più sostenibile l’ambiente di lavoro

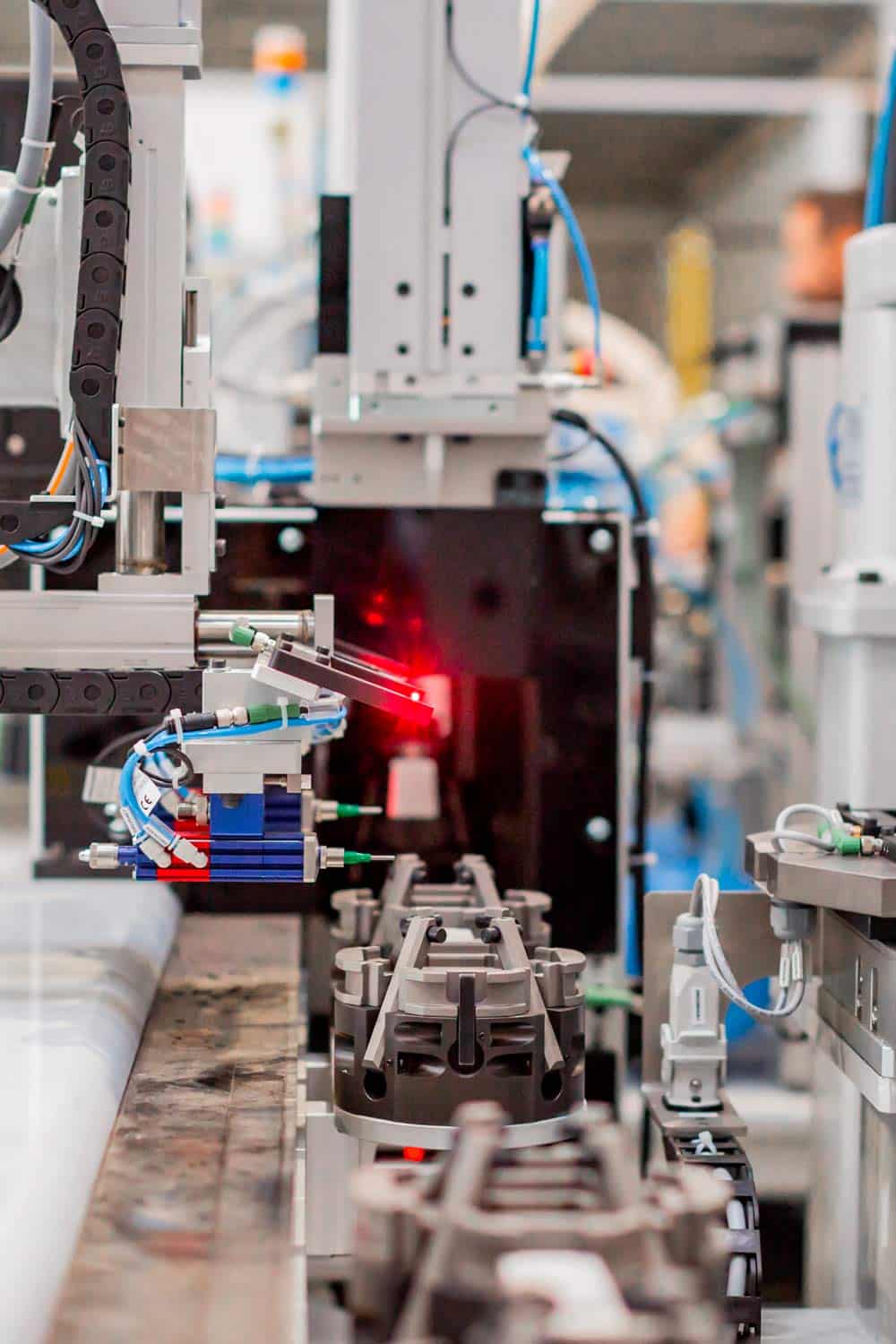

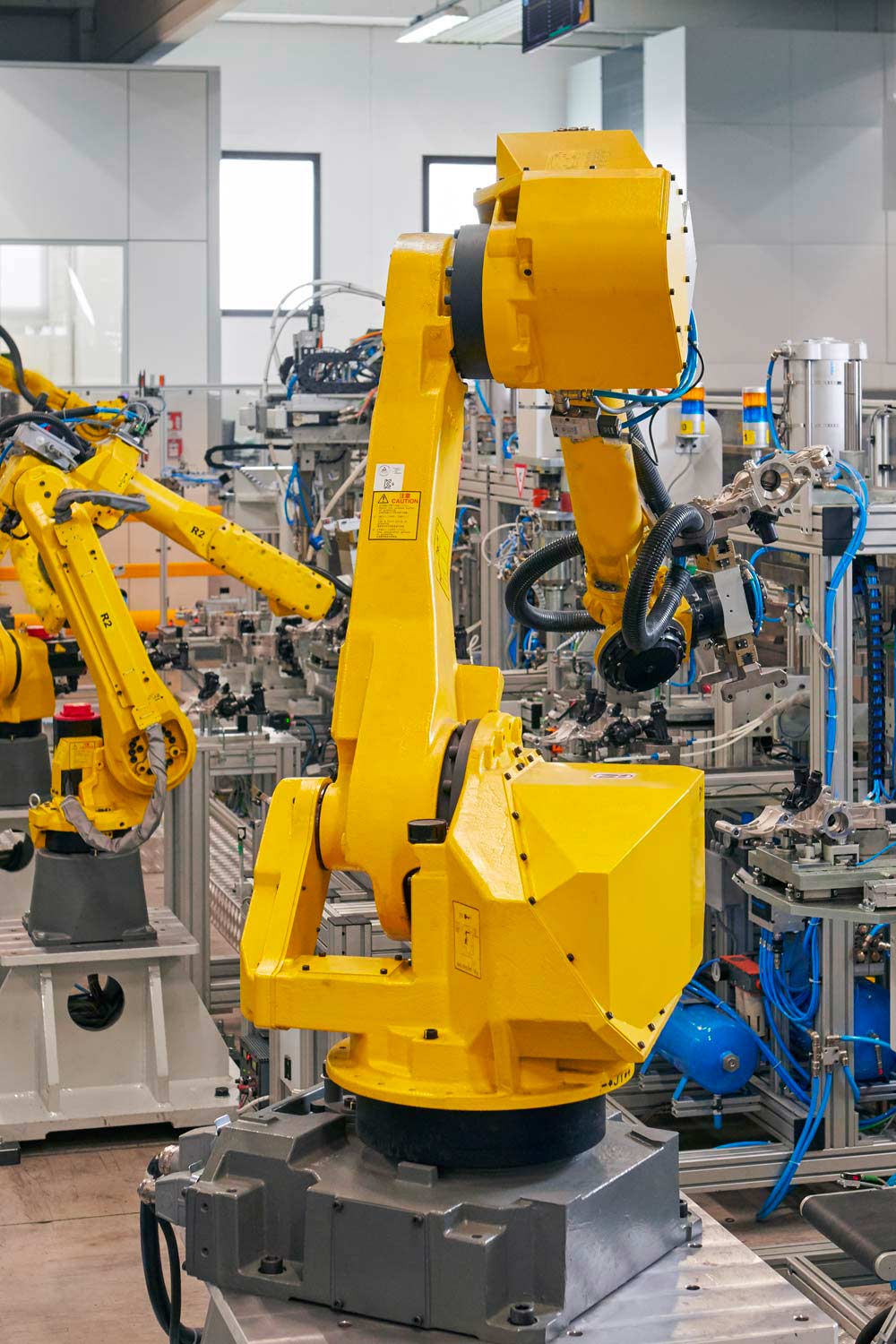

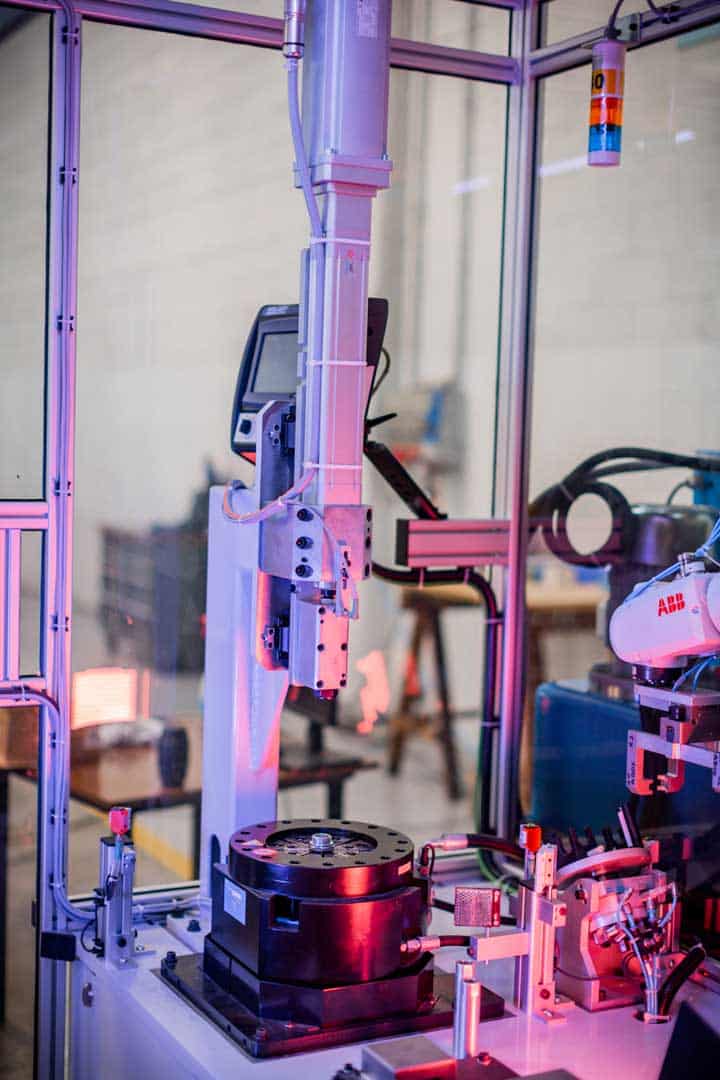

Sviluppiamo, progettiamo e realizziamo impianti di automazione non convenzionali e sempre personalizzati con la robotica integrata, per i diversi settori dell’industria manifatturiera.

Ci posizioniamo come partner strategico, che accompagna verso l’automazione di fabbrica (Smart Factory), grazie ad un elevato know how nell’analisi, sviluppo, innovazione e tecnologia, simulazione, virtualizzazione e interconnessione.

ASCOLTIAMO

Comprendiamo le reali necessità del cliente e identifichiamo una soluzione personalizzata.

PROGETTIAMO

Ideiamo un processo smart che migliori le prestazioni e aiuti l’azienda a crescere e acquisire quote di mercato.

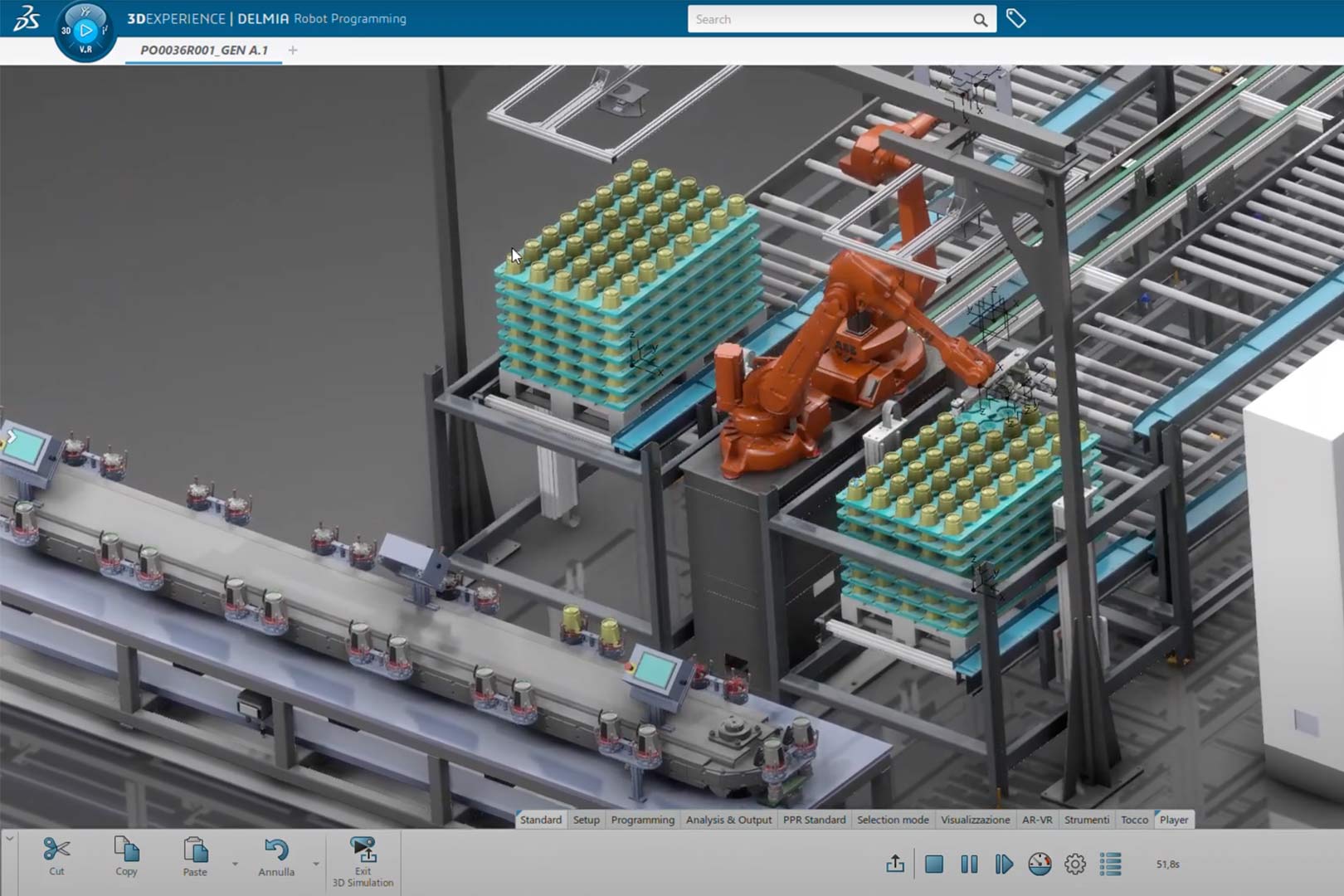

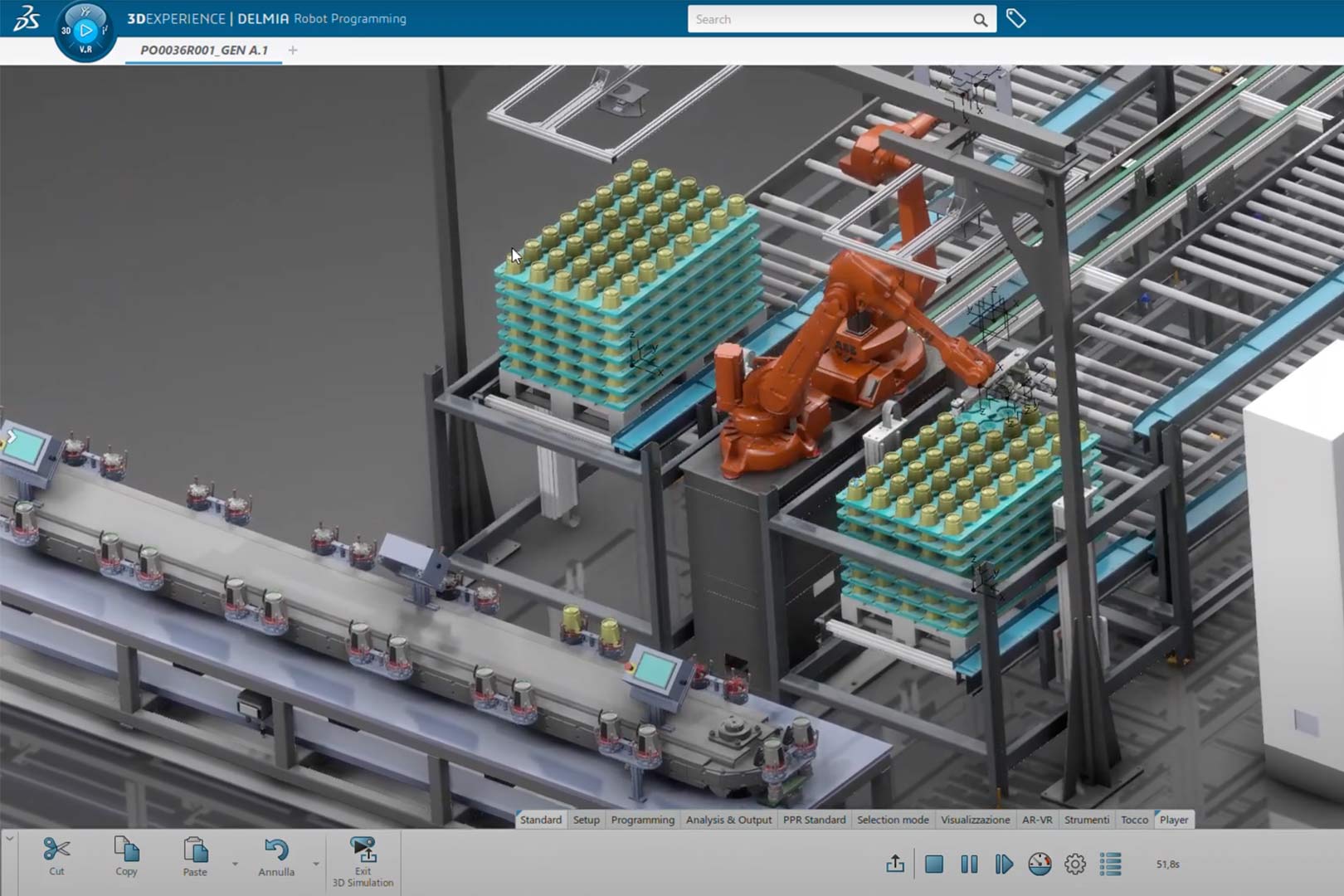

SIMULIAMO

Già nella fase di avanprogetto possiamo simulare il funzionamento della linea, misurandone preventivamente le prestazioni.

REALIZZIAMO

Diamo forma all’impianto nella nostra azienda, lo testiamo e collaudiamo sia in sede che dal cliente.

Know how ed esperienza: il connubio che ci permette di essere i partner giusti

Ideiamo, progettiamo, creiamo:

- Impianti e linee di automazione customizzati per settori diversificati;

- Sistemi di supervisione impianti;

- Strumenti per la tracciabilità dei processi;

- Simulazione e virtualizzazione dei processi;

- Sistemi di ispezione per il controllo di qualità dei prodotti e dei processi;

- Sistemi di visione 2D e 3D;

- Software per l’interconnessione di fabbrica.

Non solo, supportiamo il cliente con:

- Consulenza e affiancamento tecnico in fase pre-vendita;

- Aggiornamento costante durante tutte le fasi di avanzamento commessa;

- Assistenza post-vendita;

- Servizi di teleassistenza;

- Formazione.

Con il Digital Twin simuliamo il funzionamento dell'impianto e miglioriamo le performance, riducendo tempi e costi

Con la realizzazione del gemello digitale della linea ed il virtual commissioning siamo in grado di ridurre i tempi di realizzazione e messa in servizio, abbreviando dunque il time to market.

Ciò rende possibile:

- Ottimizzare il processo già nella fase di progettazione;

- Gestire in maniera preventiva, razionale e consapevole gli spazi, i flussi e l’interazione uomo-macchina;

- Aumentare le prestazioni e migliorare l’efficienza produttiva;

- Migliorare gli ambienti di lavoro;

- Ridurre i fattori di rischio e gli imprevisti, e di conseguenza errori e costi di realizzazione.

Ascoltiamo le tue necessità e realizziamo

un impianto di automazione personalizzato

Il nostro obiettivo è aiutarti a risolvere una problematica,

riqualificare le tue risorse e rendere i tuoi processi più smart.

Competenza

Abbiamo un profondo know how tecnico che ci permette di offrire progetti all’avanguardia.

Responsabilità

Siamo dei partner tecnologici coinvolti e competenti che mantengono sempre l’impegno preso.

Professionalità

Sviluppiamo idee che fanno la differenza nell’efficientamento produttivo.

Le certificazioni ottenute

Le attestazioni che dicono come lavoriamo

La testimonianza di chi ci ha scelto

Il simbolo del nostro impegno

Vuoi prepararti per il futuro e rendere la tua azienda il leader di settore?

Ci poniamo come Main Contractor di soluzioni integrate e possiamo accompagnarti in tutte le fasi di ideazione del tuo nuovo impianto automatizzato.

Siamo certificati

Siamo certificati